Gold mining is an industry that has been around for thousands of years, evolving with time in the methods used to extract gold from various ores. One of the most effective and commonly used processes today is the cyanidation process, which utilizes sodium cyanide to isolate gold from mined ore. While highly effective, this method has raised environmental and safety concerns, prompting the industry to adopt stringent measures to minimize impacts on ecosystems and human health.

What is Cyanidation?

Cyanidation, also known as the cyanide process, is a hydrometallurgical technique that extracts gold from low-grade ore by converting the gold into a water-soluble coordination complex. It is the most commonly used leaching process in gold extraction. The process was introduced in the late 19th century and has been a staple of gold mining ever since.

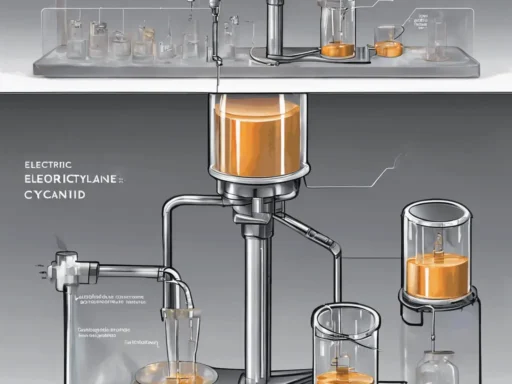

The Chemical Reaction of Cyanidation

The success of the cyanidation process lies in its simplicity and the specific chemical reactions at its core. Gold is leached from the ore using an alkaline cyanide solution. The chemical reaction can be described by the following equation:

In this process, oxygen plays a critical role as it is essential in the dissolution of gold. The presence of oxygen helps to oxidize the gold and allows it to dissolve into the solution. The dissolved gold then forms a complex ion with the cyanide

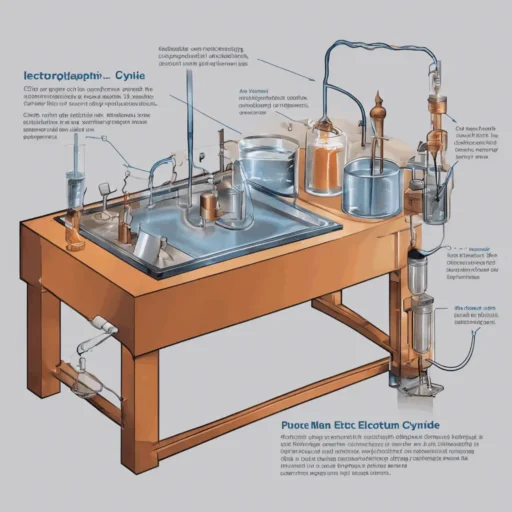

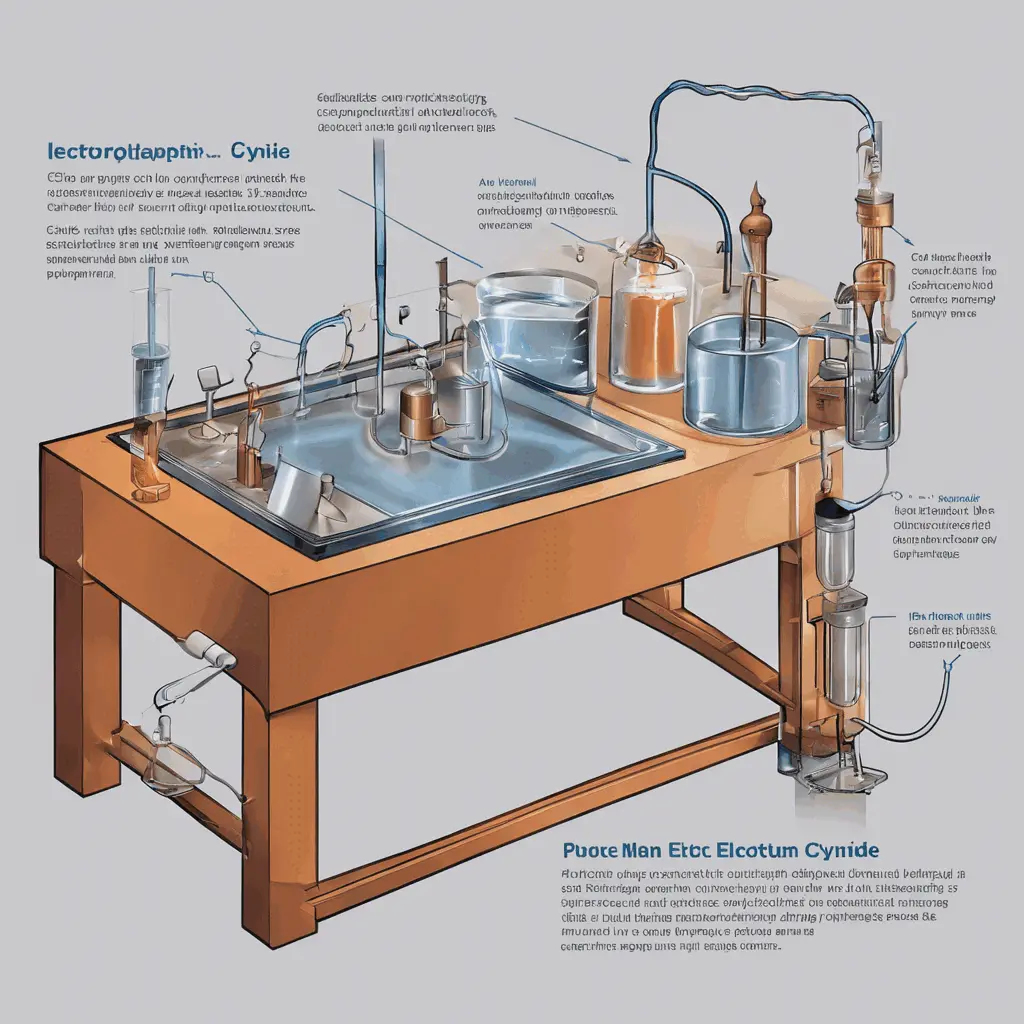

Carrying Out the Cyanidation Process

The cyanidation process typically occurs in two main steps: leaching and adsorption.

- Leaching: During this stage, the ground ore is mixed with a cyanide solution in large tanks. This mixture is stirred and aerated to increase the contact between the cyanide and gold particles. The gold dissolves into the solution over several hours.

- Adsorption: After leaching, the gold-bearing solution is separated from the solid particles. The solution, containing the gold cyanide complex, is then processed to recover the gold. Typically, activated carbon is used to adsorb the gold from the solution. The gold-loaded carbon is then treated at high temperatures to elute the gold into a recovery stream, from which pure metallic gold is eventually precipitated.

Environmental and Safety Measures

The use of sodium cyanide, while effective, poses significant environmental and safety risks. Cyanide is a highly toxic chemical, and its use in gold mining has led to concerns over its potential environmental impact, particularly the poisoning of water sources and harm to aquatic life.

To mitigate these risks, the mining industry has implemented several key practices:

- Cyanide Management: Modern mining operations use a closed-circuit system for cyanide management that prevents the release of cyanide into the environment. This includes the recycling of cyanide-containing solutions and the detoxification of tailings.

- Tailings Management: Tailings, the byproducts of ore processing, are treated to reduce the concentration of cyanide to safe levels before disposal.

- Monitoring and Regulation: Continuous monitoring of water and soil quality around mining sites ensures that any leak or spill is detected early and addressed promptly. Additionally, international standards and regulations, such as the International Cyanide Management Code, provide a framework for the responsible management of cyanide in gold mining.

Conclusion

The cyanidation process remains a vital method for extracting gold from ore due to its efficiency and effectiveness. However, the toxic nature of cyanide and its potential environmental impacts require that it be used with the utmost care and responsibility. Through stringent operational standards, careful monitoring, and ongoing research into safer alternatives, the gold mining industry continues to strive toward minimizing its environmental footprint while meeting the global demand for gold.